Managing Sluggish and Near-Expiry Inventory: Practical Solutions for Item Rotation

Slow-moving and near-expiry inventory is “silent risk.” It ties up cash, clutters operations, and suddenly becomes write-offs, heavy discounting, or returns. The best approach is prevention plus early rotation—not last-minute action.

1) Make the issue visible with simple reporting

Track:

-

slow movers over a defined period

-

near-expiry items over the next window

-

dead stock with no movement

Segment inventory into fast, medium, slow, dead, and near-expiry.

2) Set early expiry alerts

Early visibility gives you options—reposition, promote, or adjust replenishment—before it’s too late.

3) Issue inventory by nearest expiry

Expiry-first issuing reduces waste and improves rotation discipline across the warehouse.

4) Fix the root causes

Common causes include:

-

overbuying vs. real demand

-

too many SKUs without clear movement

-

weak regional coverage

-

market shifts and competition

Solve the cause to prevent repeat build-up.

5) Apply realistic rotation actions

-

reposition stock to higher-demand regions

-

align commercial promotions to move specific items

-

tighten reorder rules for slow movers

-

coordinate sales planning around rotation priorities

6) Tie rotation to distribution capability

Rotation works only when you can fulfill and distribute efficiently—especially across multiple cities and customer types.

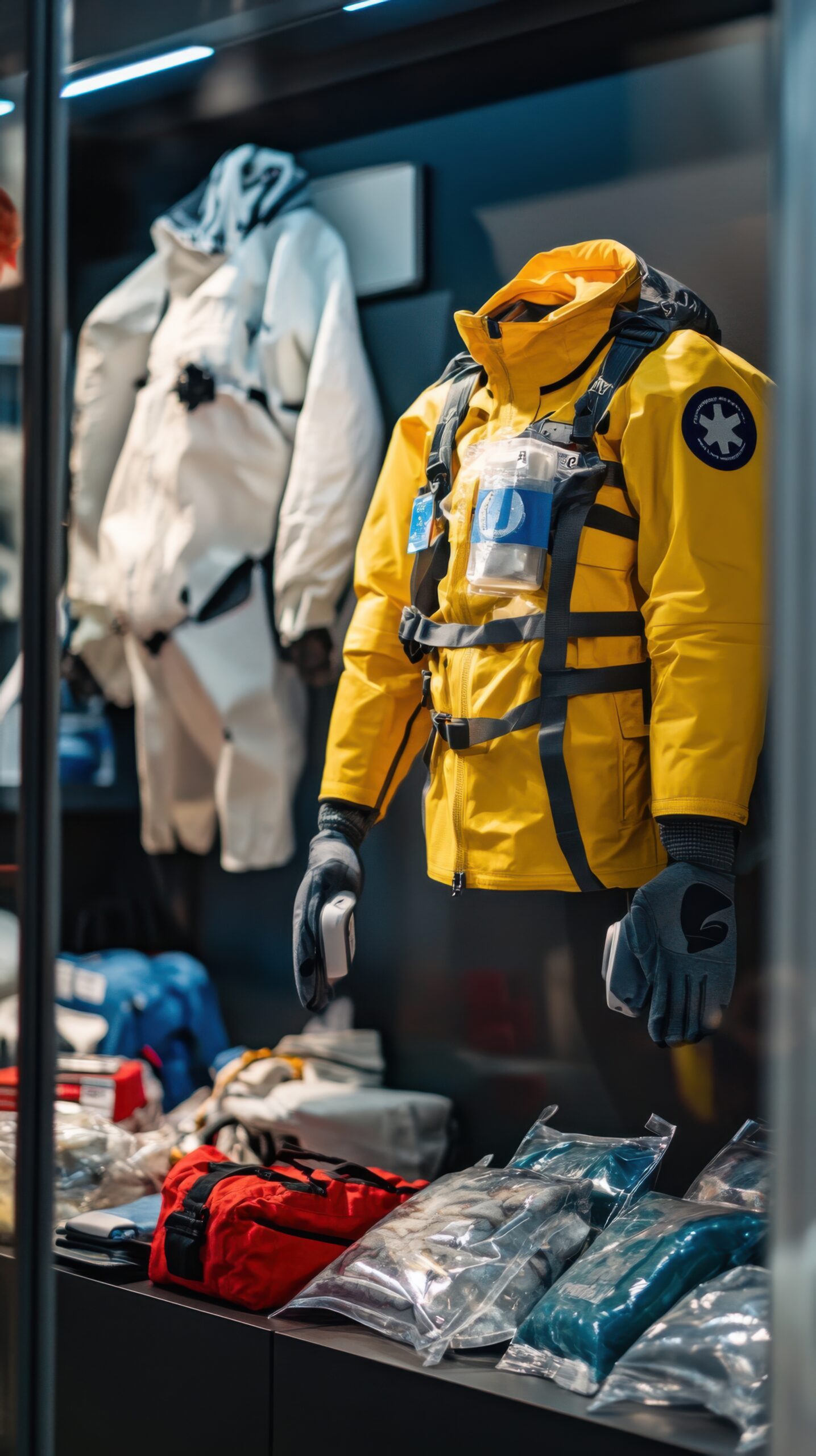

How Rabiyah Logistics supports rotation inside KSA

Rabiyah Logistics supports suppliers with warehousing, order preparation, domestic transport, and shipment consolidation—helping improve inventory rotation through structured storage operations and reliable distribution execution across KSA.

Conclusion: Early alerts + disciplined issuing + rotation actions supported by strong fulfillment and distribution can significantly reduce near-expiry losses.